High Speed Drywall Channel Roll Forming Machine

$19000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Tianjin Xingang |

$19000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Tianjin Xingang |

Model No.: YY

Brand: YY

Status: New

Applicable Industry: Advertising Company, Food Shop, Food &Amp; Beverage Factory, Manufacturing Plant, Other

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Place Of Origin: China

Warranty Period: 1 Year

Delivery Time: 30 Days

Warranty: 12 Months

Material Of Cutting Blade: Cr12

Type: Steel Frame & Purlin Machine

After Service: Engineers Available To Service Machinery Overseas

Control System: PLC

Voltage: 380V/3Phase/50Hz Or At Your Request

Cutting Mode: Servo Tracking Cutting

Way Of Driven: Gear

Forming Speed: 0-45m/min(include Punching)

| Selling Units | : | Set/Sets |

| Package Type | : | NUDE |

High Speed Drywall Channel Roll Forming Machine

Product Description

Metal stud c channel purlin drywall roll forming machine/light steel frame machine/tile making machinery Stud and track designs

Working process:

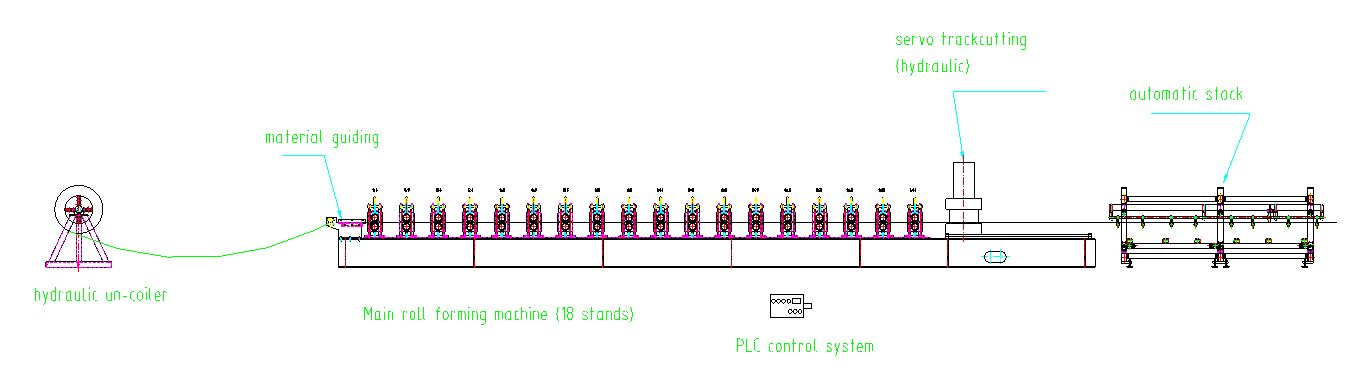

Decoiler - Feeding guide - Straighteing - Main roll forming machine - PLC control system - Servo tracking cutting - Receiving table

Technical parameters:

Raw Material

PPGI, GI, Aluminum coils

Material thickness range

0.3-1mm

Forming speed

0-45m/min(include punching) faster without punching

Rollers

12 rows

Material of forming rollers

45# steel with chromed

Shaft diameter and material

40mm, Cr12

Controlling system

PLC

Cutting mode Servo tracking cutting Material of cutting blade

Cr12 mould steel with quenched treatment

Voltage

380V/3Phase/50Hz or at your requirement

Main motor power

5.5KW

Hydraulic station power

3KW

Way of driven

Gear

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

FAQ:

Training and Installation :

1 We offer installation service local in paid, reasonable charge.

2 QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Businese Remarks:

1. Pre-sale support: 1. Drawing with material officially confirmed, 2. User manual, 3. Operation video service, 4. trouble shooting

All these support will delivery before balance payment. All accept by Buyer, then machine ship.

2. After-sale service: installation service for first loading if needed. Buyer paid the cost of trip and 100$ per day per engineer.

3. Payment term: 30% deposit paid by TT, 70% balance before shipping paid by TT,

4. Delivery time: 60 days to finish the production since deposit received

5. Warranty : 12months since delivery

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.